Our protein

Premium protein for a more sustainable aquaculture

Our protein helps to solve today's challenges of food production by reducing the aquaculture industry's environmental footprint

Fish need large amounts of protein in their feed, and the food for Norwegian farmed salmon mainly contains protein from soy, which is imported from tropical areas.

Feed accounts for up to 70–80 % of the salmon's climate footprint, and soya protein makes up the majority of this. Therefore, the farming industry has to use new feed raw materials to reduce the climate footprint.

By creating protein based on CO2 through a circular process, G2F will solve the biggest and most significant environmental impact from the Norwegian and global aquaculture industry.

Raw material from a circular process

The core of G2F's technology is unique microorganisms that capture and convert CO2 to protein. This happens because the fast-growing microorganism uses CO2 produced as waste material in the breeding facility, as food.

In this way, CO is recycled2 from production, so that it can be returned as protein in the fish feed. This provides an enormous environmental saving of up to 80% reduced CO2-emissions compared to soy production.

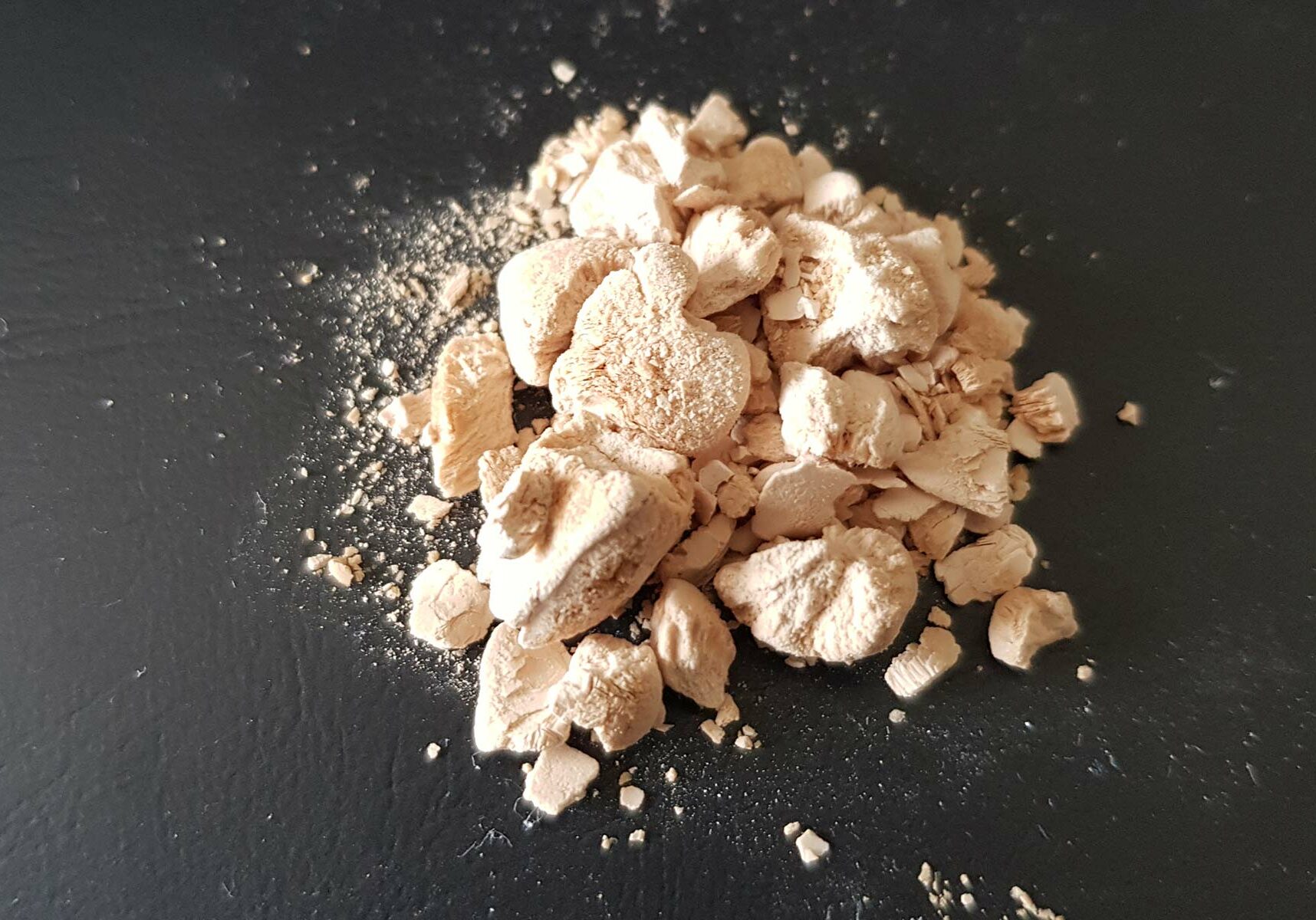

Our product is a microbial biomass containing 70-80 % crude protein. Furthermore, it contains 6–8 % fat in the form of phospholipids, 5–7 % minerals with high bioavailability and 6–8 % fibre. The product has an amino acid profile similar to fishmeal and has good digestibility.

This makes our product a high-quality protein, which can be included in the feed of several different species. In addition to the quality of the product itself, the environmental impact from production is also important in order to reduce the environmental footprint.

Reduced greenhouse gas emissions

By converting CO2 in the farms, greenhouse gas emissions from salmon production are dramatically reduced. In addition, this protein production requires significantly less land than soya production. Calculations show that we need 65,000 times less land and 2,000 times less water, compared to soy. The calculation is based on the production of 100,000 tonnes of soya in normal agriculture.

The total carbon savings will be approx. 2.2 kg of CO2 per kg round fish, compared to feed based on soy protein. Preliminary calculations show that around 30 % of the fish feed can be made from recycled CO2, with an estimated reduction of the carbon footprint of 40 %, compared to traditional farming.

The enormous environmental benefits and high quality of the product make our biomass desirable. Therefore, it is also a big advantage that the production is very predictable.

Predictable quality

The biomass is produced completely independent of the season and runs 24 hours a day, 365 days a year. This takes place completely independently of climate and weather conditions.

This industrial protein production takes place significantly faster than what nature itself manages through photosynthesis. Therefore, we can double the amount of protein every 3-4 hours, continuously. This provides the basis for a highly efficient production of protein, which can be scaled up on an industrial scale.

Through the circular production process, we contribute to reducing the aquaculture industry's climate footprint, while at the same time ensuring a continuous supply of environmentally friendly fish feed.